MIT’s Plant-Based Material Could Replace Plastics

Using a synthetic polymer and cellulose from trees, MIT researchers invented a material that “is tougher and stronger than bone, and even harder than aluminum alloys,” the lead researcher said.

[Please note that this page contains affiliate links. If you choose to purchase after clicking a link, I may receive a commission at no extra cost to you.]

Using a synthetic polymer and cellulose from trees, MIT researchers invented a material that “is tougher and stronger than bone, and even harder than aluminum alloys,” the lead researcher said.

The researcher’s goal is that their compound may lead to much better sustainable plastics for the future. But unfortunately, as of now, the material shrinks while it is drying, making printing anything substantial out of it very difficult.

Cellulose Nanocrystals (CNCs)

According to MIT researchers, if you want to determine where the most important part of a tree is, you must look very closely. It is not the sturdy roots of an enormous trunk: it is the cell walls.

The tree walls are made up of cellulose, and it creates the structure for everything from algae to the massive redwoods. Cellulose is critical as it is made from organic polymers, which are arranged tightly in crystalline patterns.

The cellulose nanocrystals (CNCs) support the cell walls. According to MIT researchers, they are more robust and stiffer than Kevlar.

So why is it that plastics are still made from petroleum rather than cellulose nanocrystals?

The issue is scale. If too many CNCs are added to a material, they start to clump together and refuse to bond with other polymer particles. Although, the MIT research team has found a way to get around that.

Cellulose Nanocrystals

The MIT researcher’s plant material, published in the journal cellulose, may contain up to 60-90% cellulose nanocrystals.

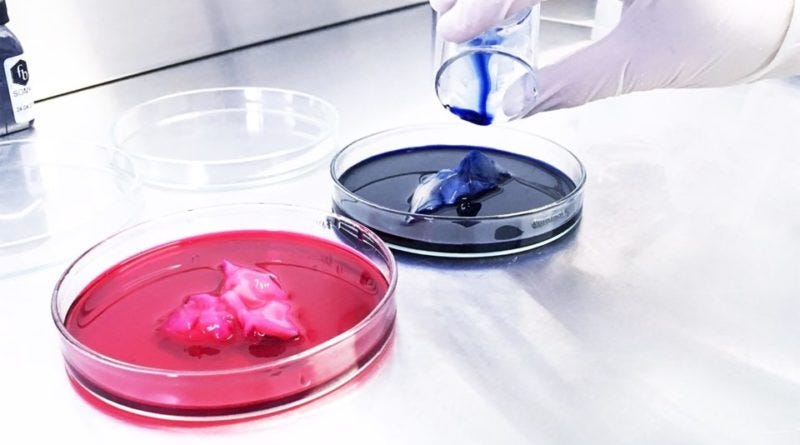

They started by mixing the synthetic liquid polymer with the CNC. By getting the ratios just right, it will form a gel. Then, to prevent the nanocrystals from clumping, researchers used an ultrasonic probe, breaking them free and merging with other molecules.

When the researchers examined the cellulose nanocrystals, they found that they were arranged in a pattern like a nacre, which is the material you eat an oyster from, made from the same material as pearls.

A Nacre structure helps to prevent a crack from going through it. The researchers found that their material had a similar resistance to cracking.

The Next Challenge

Thanks to tech, the gel is able to be 3D-printed, although it is not anywhere near ready to be fully scaled. In addition, the shrinking that occurs when it dries may cause anything too substantial to crack during its drying process.

That issue is most likely solvable, and if it is, this material may allow researchers to do a bunch of things that have never been done before.

Eventually, this material may replace plastics made from fossil fuels one day soon.